Products

Converting Machines|Feminine Care Products Machines

Feminine Napkin Machines

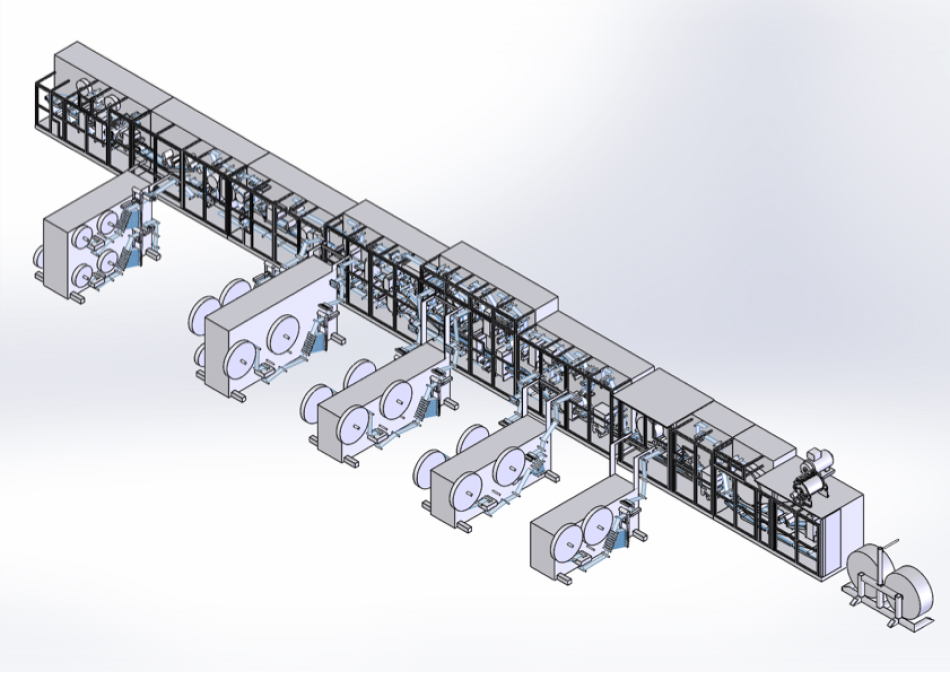

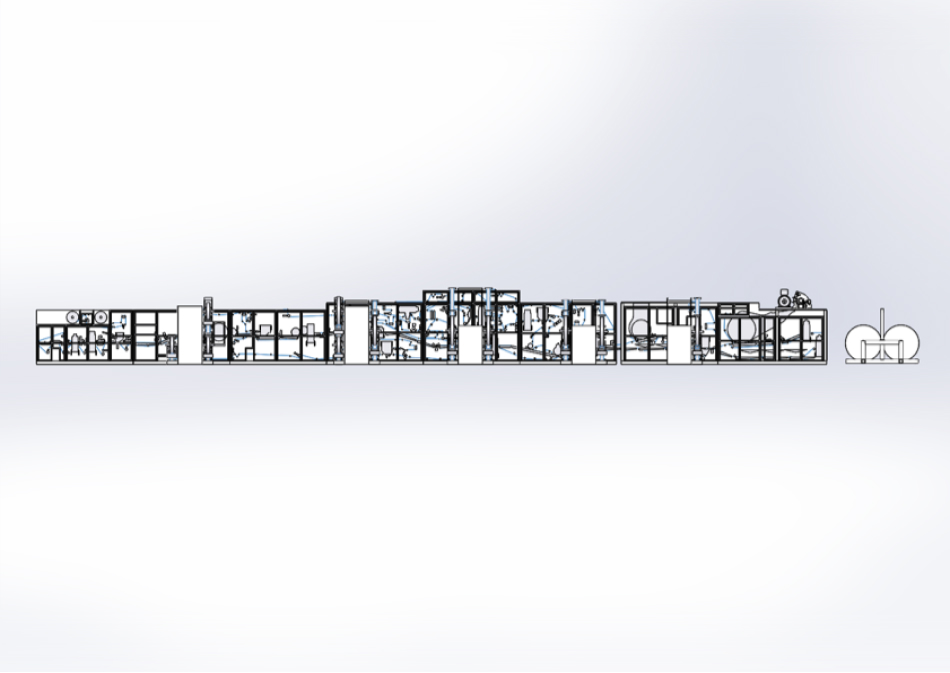

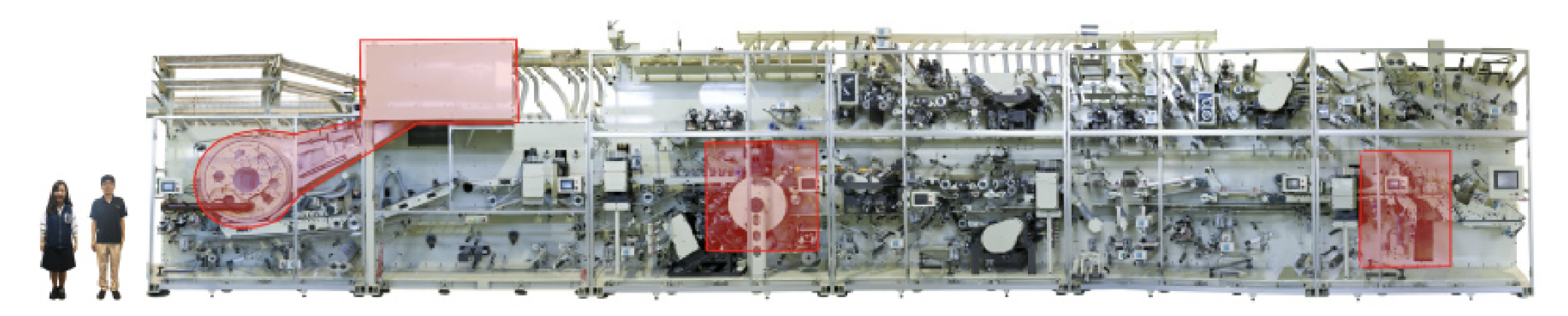

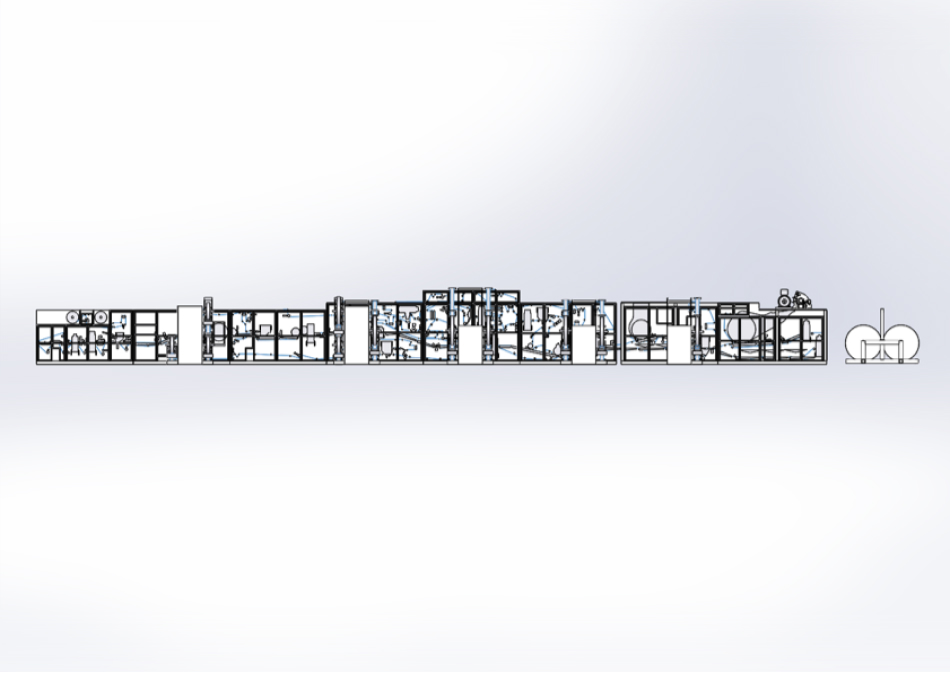

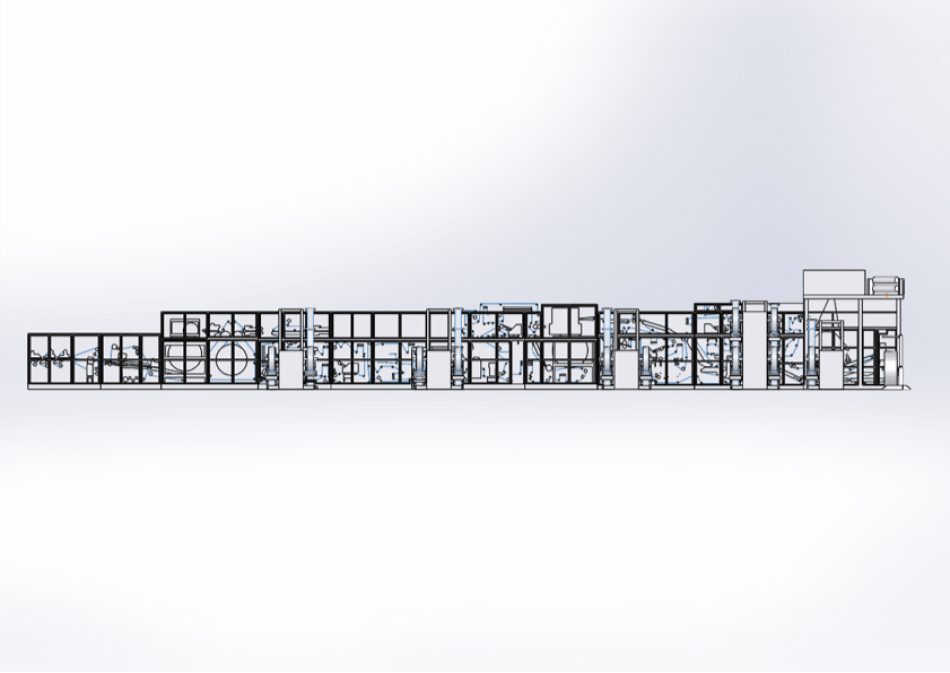

The world's first "Easy Wrap" (tri-fold and packaging integrated production line) developed by ZUIKO revolutionized the feminine hygiene industry. In many markets, this has become the standard packaging method. Over the decades, a number of engineering and manufacturing innovations have dramatically improved the quality, performance, and convenience of feminine napkins. Products are now designed for night time, exercise, discreetion, and other specific uses.

Specs

| Production Speed(pieces/minute) | Dimensions(LXWXH) | Product Sizes | Weight | |

|---|---|---|---|---|

| Premium | 1400 | 30m x 11m x 5m | 2 Sizes Possible | Approximately 100 Tons |

| Standard | 1200 | 30m x 10m x 4m | 4 Sizes Possible |

- Production Speed(pieces/minute)

- 1400

- 1200

- Dimensions(LXWXH)

- 30m x 11m x 5m

- 30m x 10m x 4m

- Product Sizes

- 2 Sizes Possible

- 4 Sizes Possible

- Weight

- Approximately 100 Tons

- Approximately 100 Tons

Basic Specifications

- ・Full Servo Drive System

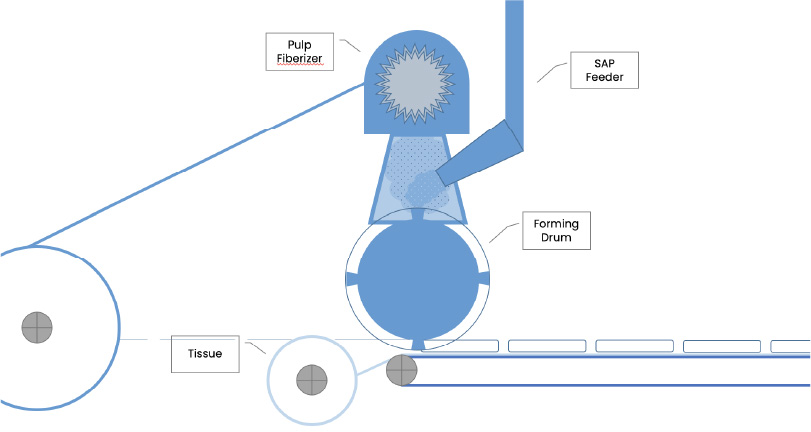

- ・Absorbent Core Forming System

- ・Auto Splice System

- ・Pulp Fiberizing System

- ・Touch HMI

- ・Safety Door Switches

- ・Individual Packaging System

- ・Power Consumption: 500-600 kVA

- ・Air Consumption: 8,000-12,000

Options

- ・Top Sheet 3D Emboss System

- ・Contact ZUIKO?for Optional Features and Details

Image

Feminine Napkin Pants Machines

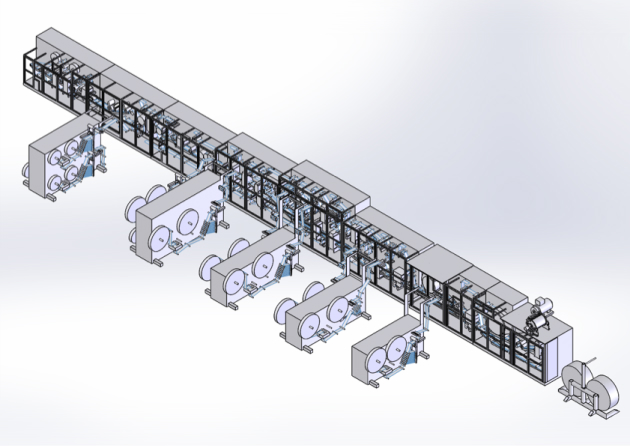

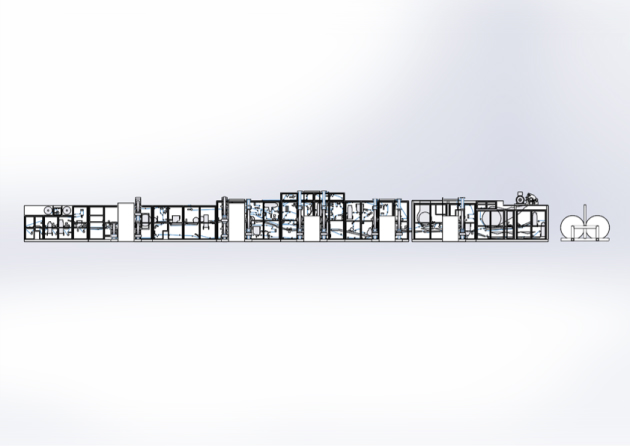

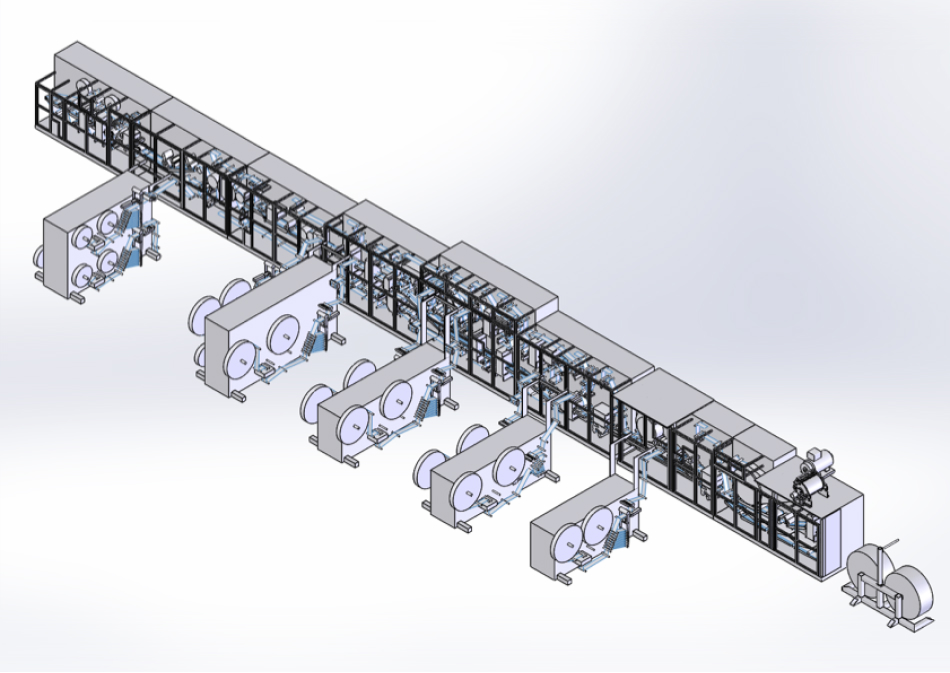

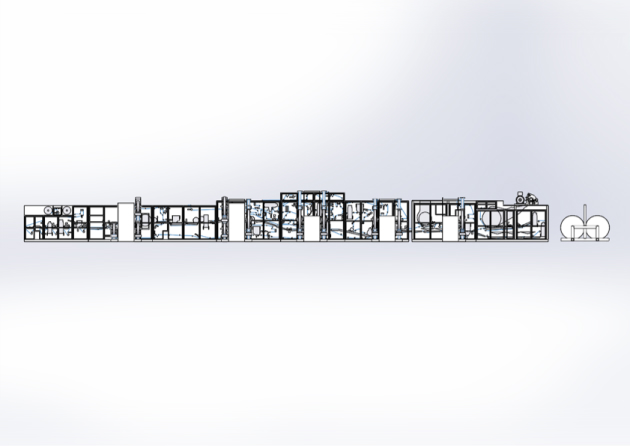

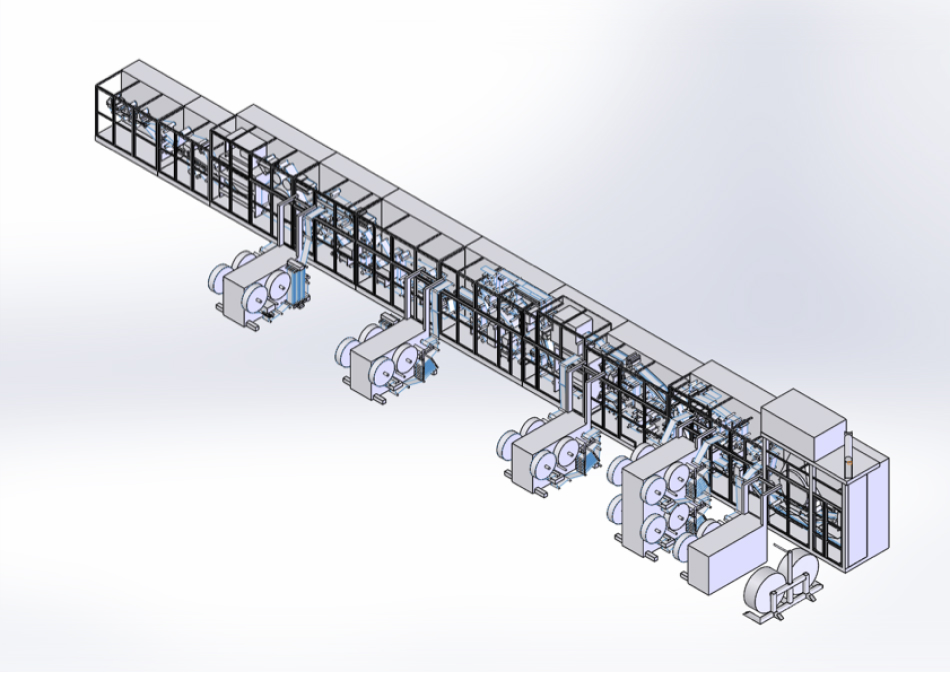

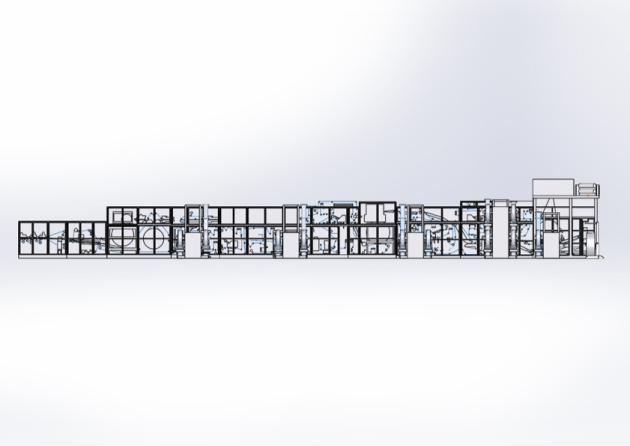

A new product gaining popularity in Asia, disposable pants for feminine hygeiene are designed for either night use or as substitutes for normal underwear when menstral flow is particulary heavy. ZUIKO's napkin pants machines share the same advanced and reliable technologies used in baby and adult pants diaper machines. Production is stable and efficient.

Specs

| Production Speed(pieces/minute) | Dimensions(LXWXH) | Weight (Tons) |

|---|---|---|

| 600 pieces/minute | 32m x 8m x 4m | Approximately 100 Tons |

- Production Speed(pieces/minute)

- 600 pieces/minute

- Dimensions(LXWXH)

- 32m x 8m x 4m

- Weight (Tons)

- Approximately 100 Tons

Basic Specifications

- ・Full Servo Drive System

- ・Absorbent Core Forming System

- ・Auto Splice System

- ・Pulp Fiberizing System

- ・Touch HMI

- ・Safety Door Switches

- ・Individual Packaging System

Options

- ・Top Sheet 3D Emboss System

- ・Contact ZUIKO?for Optional Features and Details

Image

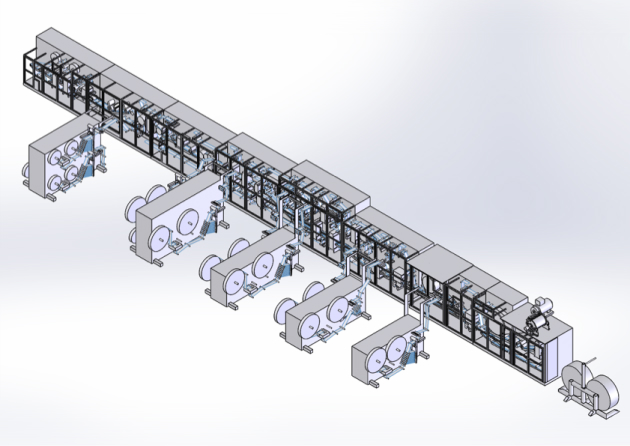

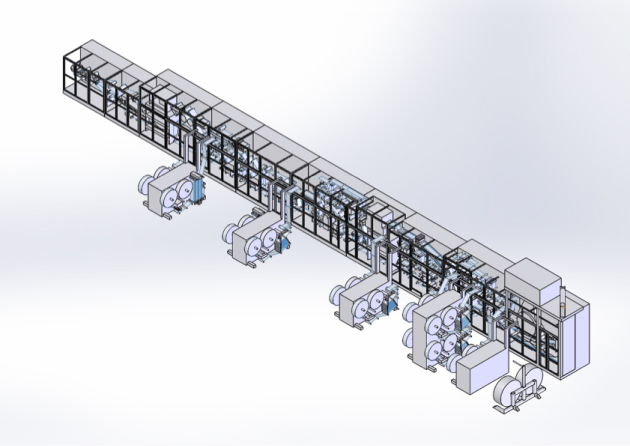

Pantyliner Machines

ZUIKO high speed processes and converting technologies are also found in products with seemingly simple structures. Made for discreet undergarment protection, ZUIKO designed pantyliner machines can produce products at very high speeds while maintaining high quality and stable production.

Specs

| Production Speed(pieces/minute) | Dimensions(LXWXH) | Weight (Tons) |

|---|---|---|

| 1,000-2,000 pieces/minute | 20m x 8m x 4m | Approximately 100 Tons |

- Production Speed(pieces/minute)

- 1,000-2,000 pieces/minute

- Dimensions(LXWXH)

- 20m x 8m x 4m

- Weight (Tons)

- Approximately 100 Tons

Basic Specifications

- ・Full Servo Drive System

- ・Absorbent Core Forming System

- ・Auto Splice System

- ・Pulp Fiberizing System

- ・Touch HMI

- ・Safety Door Switches

- ・Individual Packaging System

Image