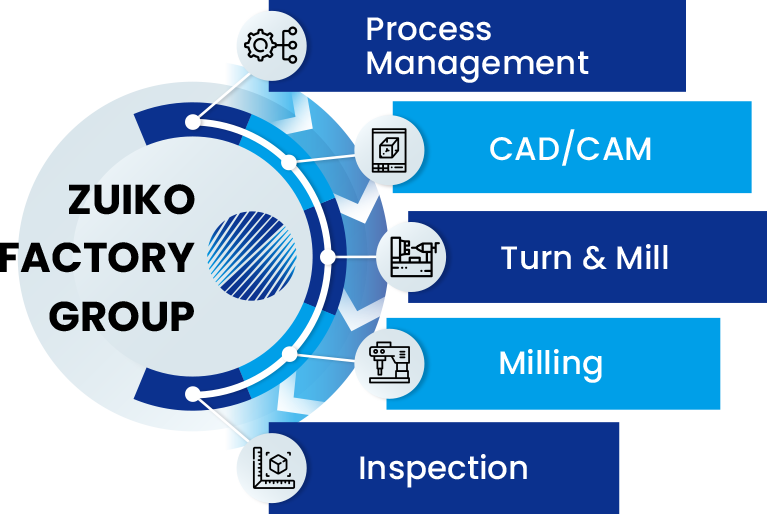

Process

Management Group

Group Role

Providing the overall management and support for manufacturing parts, the group requires various analytical and communication skills. Of course, cost reduction activities are also important.

Main Business Content

Material Arrangement

The specified raw materials are ordered and machining is scheduled based on the machining instructions. Since our main business is a combination of high-mix, low-volume production, the cost of materials is considered each time when deciding on a supplier and while making arrangements for heat treatment and surface treatment with outside vendors.

Process Control

A ZUIKO Machine consisting of more than 100,000 parts cannot be completed if even one part is missing.

Meticulous internal and external process control ensures that the parts delivery date is met.The Inspection Group deals with any in-house processing trouble including on-site support.