ZUIKO is the largest manufacturer of machines for the production of diapers and sanitary napkins in Japan.

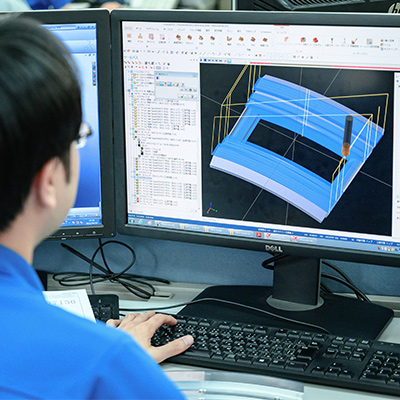

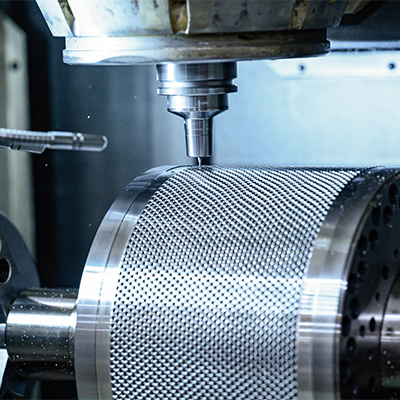

The precision machining and milling of the parts for these machines are produced by the Processing Technology Department.

ABOUT US

Continue to provide highly original and “anything that can exceed expectations” with comprehensive strength through our integrated production system.

Developing new processing technologies based on our knowledge and expertise in high-mix and low volume production.

We take pride in being ZUIKO's high-value-added parts manufacturing department, and aim for the best in terms of quality, cost, and delivery.

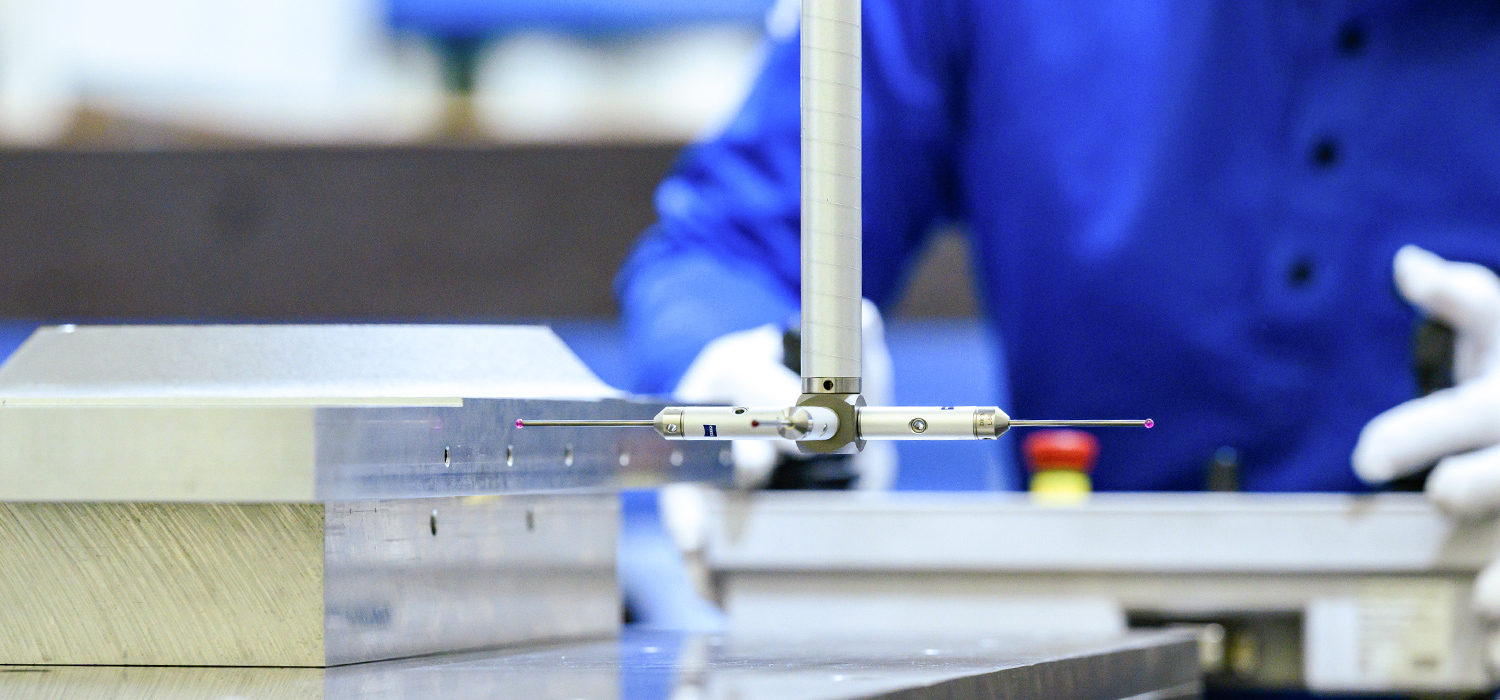

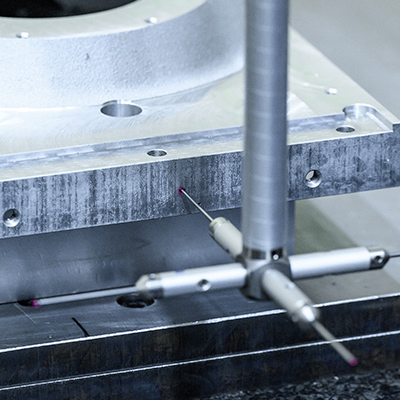

QUALITY

ZUIKO exports sanitary product manufacturing equipment to 36 countries around the world.

Our Processing Technology Department contributes to the world with metal processing parts that have passed the strict quality inspection required for sanitary products.

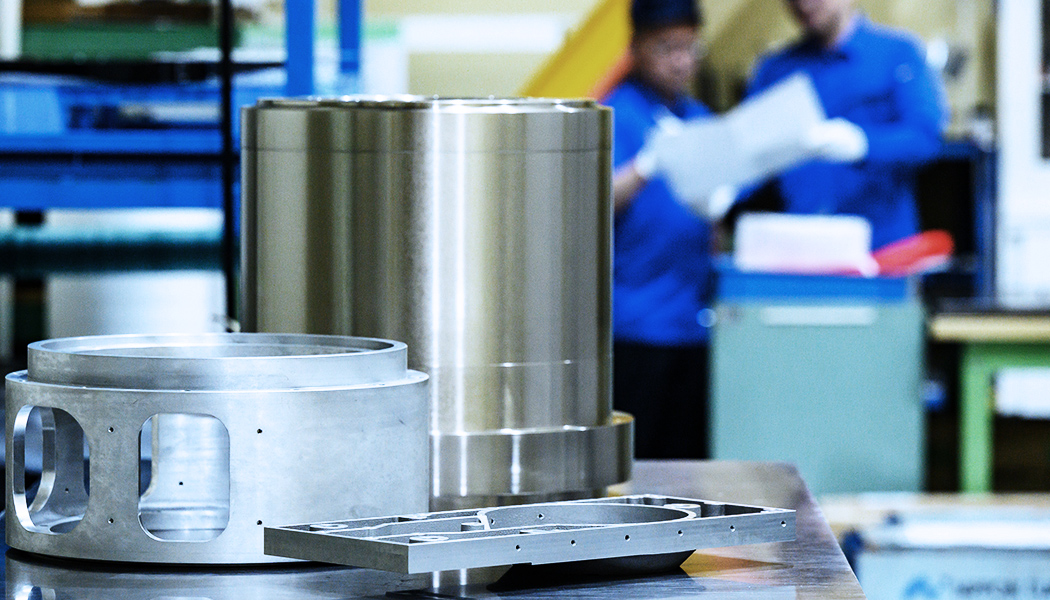

GOOD PRODUCTS

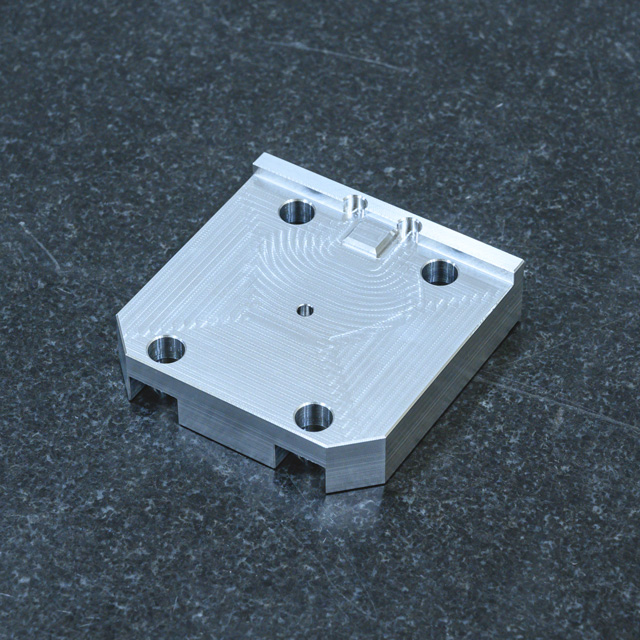

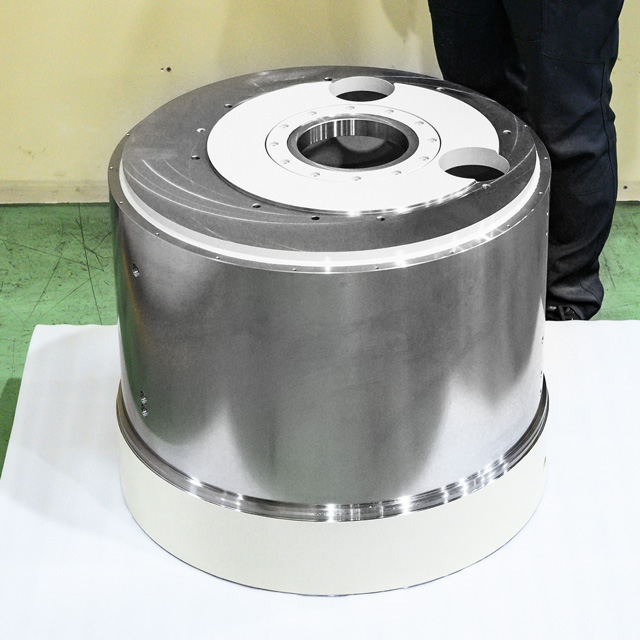

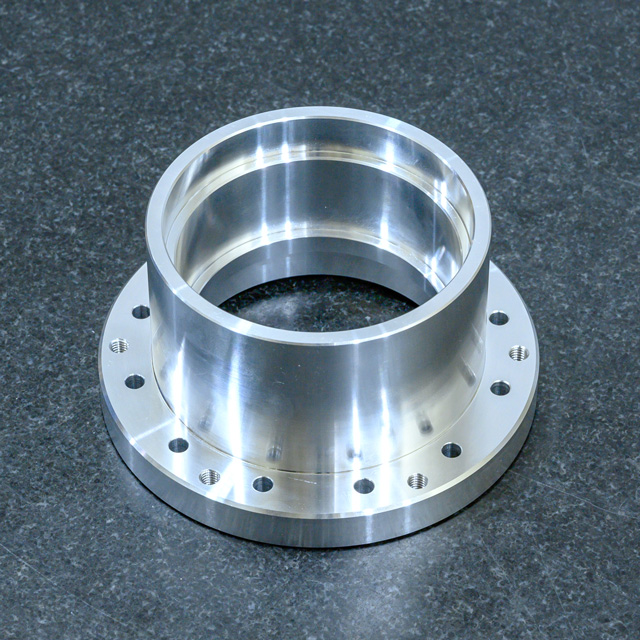

WORKS

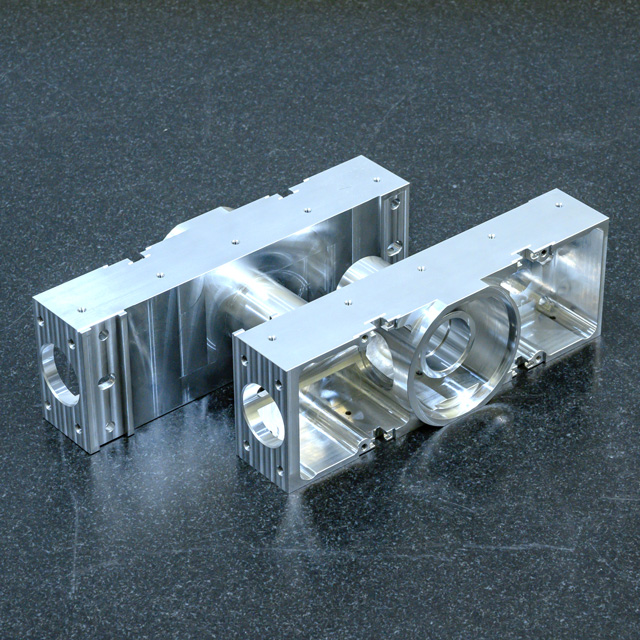

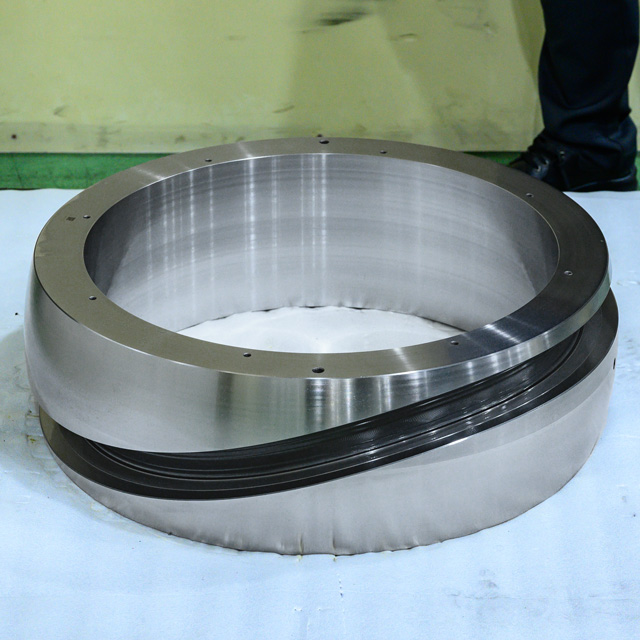

Examples of

Manufactured Parts

The Processing Technology Department has continued to meet the needs of customers around the world and has created many highly original parts. ZUIKO built machines are the culmination of these high-performance parts.

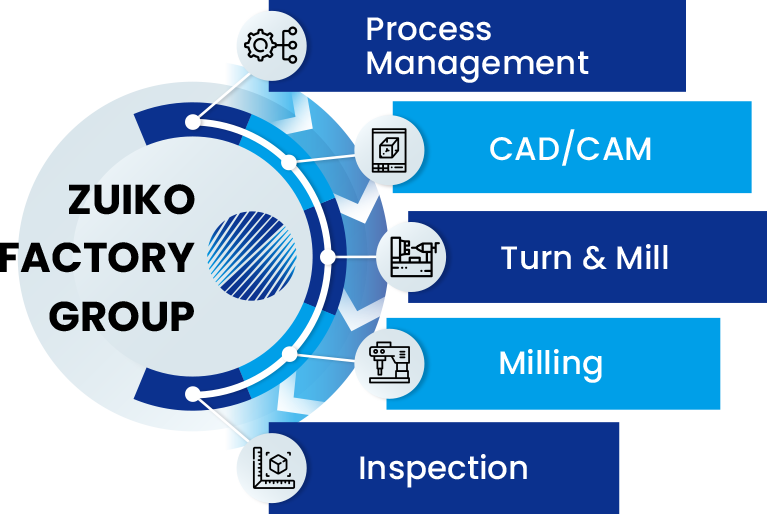

GROUP

Integrated production

is done in-house by 5 groups

The five groups handle everything from material procurement to final inspections. The unique production structure is the combination of each group’s specialized technology.

Though close teamwork, the integrated in-house production system enables high quality production and quick delivery.

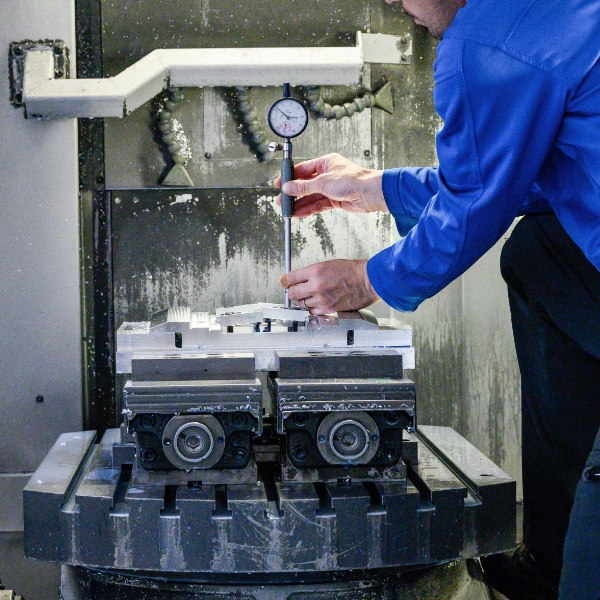

FACTORY & EQUIPMENT

Factory and equipment that

supports ZUIKO technology

In order to respond to various machining specifications, the Processing Technology Department is equipped with a 5-axis CNC machining tool and other state-of-the-art manufacturing equipment. From data security management to the calibration of inspection equipment, tasks essential to maintain the highest quality are done each day.