Factory/EquipmentIntroduction

Production Equipment

Managing parts production using

state-of-the-art manufacturing

equipment and production solutions.

Any part suitable for all-round use.

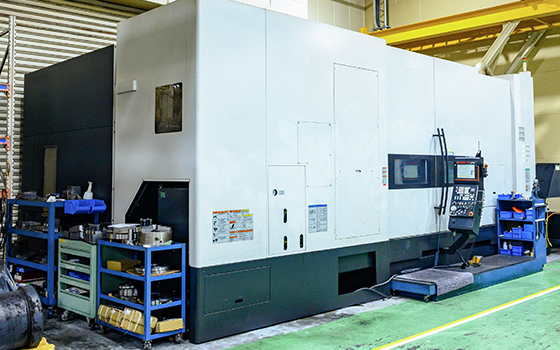

Equipped with state-of-the-art machining tools and a temperature controlled inspection room, various solution including production control systems are managed.

In addition to the parts processing area, the material receiving and storage area is spacious and well-secured.

Various equipment other than machine tools completes the department's integrated production system.

Combination CNC Lathe

Horizontal Machining Center

Vertical Machining Center

CNC Cylindrical Grinder

Surface Grinder

CAD/CAM

Tsuruno Factory

Since the start of operations in 2009,

the machining and milling factory has

developed along with the innovative

growth of ZUIKO's converting machine

technology.

A manufacturing company's fabrication and machining department having its own spacious and independent plant is rare. Implementing the latest tools and technologies, the Tsuruno Factory Group aims to embody the concept of “Make the Impossible Possible.”

Access

By train

7 minutes walk from Settsu Station on the Osaka Monorail Main Line

By car

About 15 minutes from Meishin Expressway, Suita IC Exit via Route 2 to Osaka Chuo Kanjosen