QUALITY CONTROL

Quality Control System

To maintain “ZUIKO Quality,” quality

improvement activities and a traceability

system was implemented. Inspections

are made to all out going parts to prevent

delivery of questionable parts.

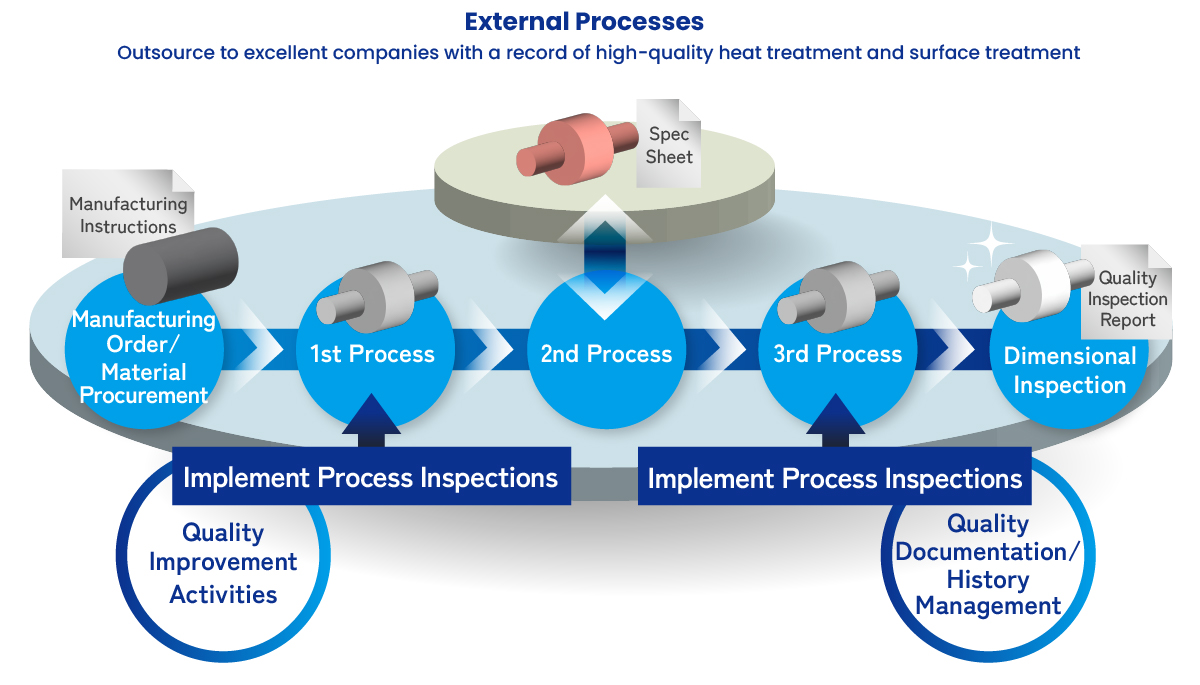

The inspection group plays a central role in conducting quality inspections and quality improvement activities. Each group works together to improve quality and achieve its mission of zero nonconformity issues. In addition, the same level of inspection done on in-house made parts is required of any outsourced parts done by vendors to ensure the same level of quality.

Company Structure

Process Management

Starting from the process management group, each team and vendors work together to build in quality.

Quality Assurance

Inspect with various instruments and record measurements to determine if the product is finished according to the drawing.

Quality Improvement

In our efforts to improve product quality, we find the root cause to any problems by considering various factors and analyzing clues.

Inspection Equipment

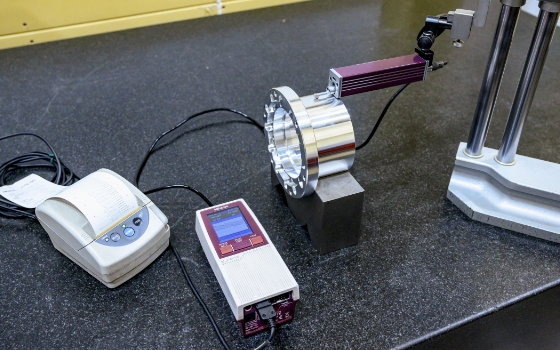

Machined parts, which are directly linked to the quality of sanitary goods, are inspected for quality using a full range of inspection equipment.

Preventing the delivery of non-conforming parts with reliable inspection skills and know-how.

Inspections are performed in a temperature controlled room using a variety of measuring instruments that can measure special and unique shapes using various jigs. All parts are inspected to the μm (1/1000mm) and measurements are recorded showing proof of reliable quality.

Three - Dimensional Measuring Machine

Digital Microscope and ZUIKO designed 3-axis Camera Platform

Surface Roughness Tester

Inspection Records

Inspection data are recorded in a unique form that supports high-mix, low-volume production. For customers with specific requirements, we can provide a dedicated inspection form.

About Shipping

All shipments are packed carefully and reliability before delivery.