すべてのお客さまに、

期待を超える衛生用品製造機を

お届けします。

Why ZUIKO

ZUIKOとは

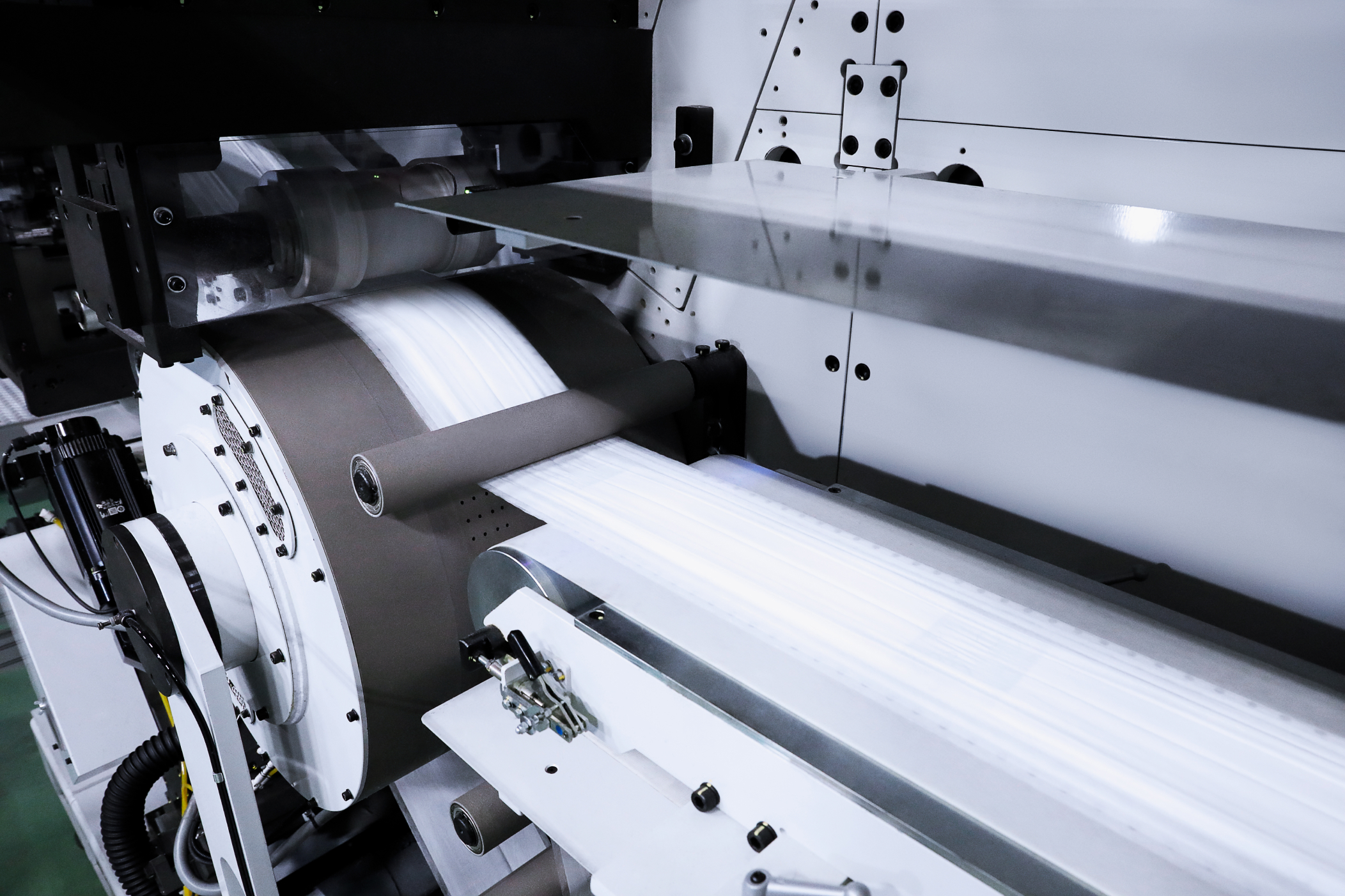

衛生用品製造機の開発・製造から

コンサルティングまで

グローバルに展開

独自の技術力と独創性を強みに、

国内シェア90%、

世界でもトップ3に入る

衛生用品製造機メーカーとして

成長を続けています。

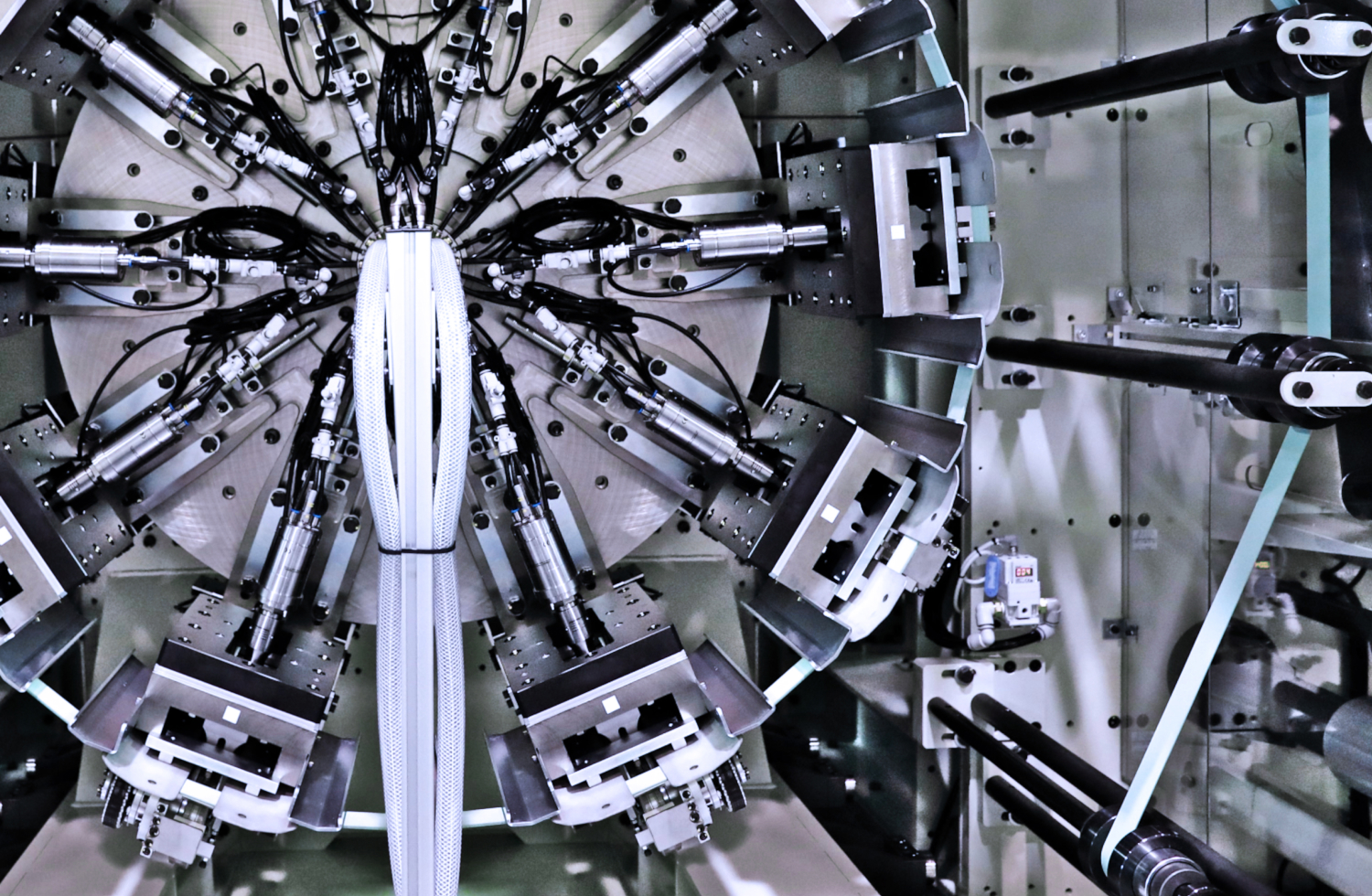

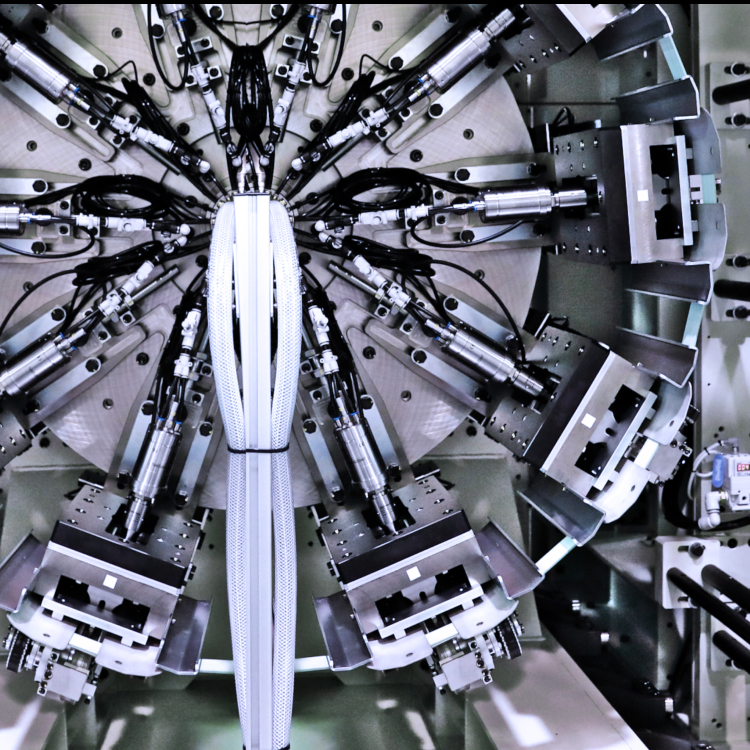

TECHNOLOGY

ZUIKO独自の技術

お客様のニーズを

先取りした製造機の

開発によって培われた

特許技術の数々

国内外で800件を超える特許を保有。

市場ニーズを先取りした

新技術の開発に取り組んでいます。